A Control Plan is a method for documenting the functional elements of quality control that are to be implemented in order to assure that quality standard are met for a particular product or service. The intent of the control plan is to formalize and document the system of control that will be utilized.

Description: A Control Plan is a method for documenting the functional elements of quality control that are to be implemented in order to assure that quality standard are met for a particular product or service. The intent of the control plan is to formalize and document the system of control that will be utilized.

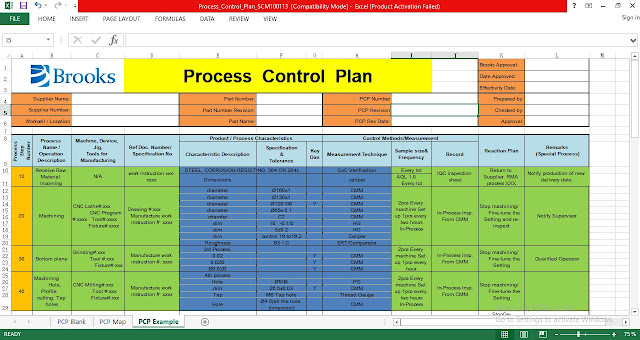

Example: A company is preparing to transition into production a redesigned, small electric motor. One of the critical parts of the motor is the metal shaft. A portion of a control plan for the machining of the shaft is given below.

Typically, the control plan may also include other items like the frequency with which the process is reviewed, verification that the measurement system is capable, typical corrective actions to be taken in the presence of out-of-control conditions, any special inspection requirements, and a history of the process capability measures.

Note that the control plan is a basic working document for quality engineering (in both manufacturing and service). One should be able to review the control plan and quickly understand the elements of quality assurance being utilized.

And remember, this example is a manufacturing example. The same technique can be applied to any process (services industry, back-office, transactional processes). The team should use a control plan to ensure that the process does not slip back into the ways of the old process.

Reference: sixsigmadaily

0 Comment: